Please note: you can view or download this article as a PDF (click here)

Bus/Motorhome Fires – Prevention, Detection and Suppression

Written for Bus Conversions Magazine by

Jim Shepherd, RV Safety Systems

Please note, the following information was submitted to Bus Conversions Magazine (http://www.busconversions.com). It was published in their March 2004 with only minor editing. I have posted the complete transcript here, since some of the edited material might be of interest to the reader.

Major Causes of Bus/Motorhome Fires

Bus conversion and motorhome fires do not occur often, but when they do they are always devastating to the owner. We have all seen pictures of the damage that can occur and it often results in total destruction of the vehicle and its contents. Fortunately, most occupants escape serious injury or death.

Many bus fires begin in the engine compartmentcreating a total loss of the bus.

If a bus fire cannot be battled safely, then you should not attempt

to battle the flames. Personal safety is the overriding consideration.

There are many causes of fires in these kinds of vehicles. Most often the fires occur in the engine compartment, the generator compartment or involve brake-related fires. Of course, there are also interior fires caused by cooking and smoking accidents, but this article will not address interior fires.

Two excellent case studies exist which detail causes of bus fires. They are titled “Bus Fires in Finland during 2000” (and 2001). They can be found on the internet at the following locations:

2000 study: www.onnettomuustutkinta.fi/uploads/6hdieo2.pdf

2001 study: www.onnettomuustutkinta.fi/uploads/gvty79bpq89a.pdf

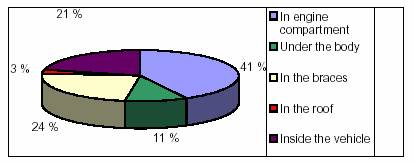

Origins of fire, 2000

Origins of fire, 2001

The 2000 report details 33 bus fires involving buses manufactured from 1983 to 2000, while the 2001 report details 38 bus fires involving buses manufactured from 1985 to 2001. Engine compartment fires accounted for 64% of the 2000 fires and 41% of the 2001 fires. The second leading contributor to bus fires was brake related fires – 21% in 2000 and 24% in 2001. The other significant contributor was electrical system related

Engine compartment fires can be attributed to the numerous flammable fluids found in the general area, coupled with an excellent ignition source – high-temperature exhaust system components. The flammable fluids include hydraulic, transmission, power steering, and fuel.

The causes of brake related fires are less obvious. We understand the very high temperatures that can occur from excessive brake usage, or a dragging brake, but what is the “fuel” source? Most often the high temperature causes the axle seals to fail and the grease or oil from the bearings or differential leaks onto the very hot surfaces and ignites. If not detected quickly, the fire will spread to the tire. When that happens, it is extremely difficult to extinguish the fire.

This article will not deal with electrical fires caused by wiring problems. The many articles and books written by George Myers and others detail well-designed electrical systems. If one follows those recommendations, applicable regulations and/or acceptable wiring standards, the risk of an electrical fire from a wiring defect will be minimal.

What can the Bus/motorhome owner do to minimize the chance of a fire or minimize the damage from a fire if it occurs?

Without question, inspections of critical systems should be a standard part of each day’s trip. Before we pull out each day, we should do a pre-trip inspection. This daily inspection should involve many of the elements described in CDL (Commercial Driver License) book’s pre-trip inspection procedure. I have a very strong opinion that a full “pre-trip” inspection (per CDL procedure) should be done at least once a month if the bus has been driven during that period. The CDL manual is an excellent information resource and it is free. You can obtain one at most drivers’ license testing locations or it can be downloaded from the internet. Most states have a website for CDL manuals. One such site is:

http://www.dmv.state.va.us/webdoc/citizen/drivers/cdlmanual/

While the pre-trip inspection is very important, the “rest stop” inspections are even more important. At each stop we should do a quick “walk around inspection”. This involves quickly looking for leaks, doing a “smell check” as you walk around the vehicle, and touching each tire and wheel hub to make sure that the temperatures are reasonable (you should be able to leave your hand on the wheel or hub without feeling any “burning” sensation). The temperature check of the hubs should take into consideration the amount of braking done prior to the rest stop – all bets are off if you stop at the bottom of a big hill.

If you do not feel that you are capable of doing a proper safety inspection, any major truck repair shop will have a qualified mechanic that can do a defined DOT Safety Inspection.

From a fire-related standpoint, there are systems that should receive detailed inspections at frequent intervals:

- Fuel system

- Electrical wiring

- Exhaust system

- Brake system

These are obvious, but we still need to remind ourselves to inspect these systems. With the exception of the brake systems, the process is simple and does not take much time. For the fuel system, we are looking for leaks and hoses or tubing that look questionable. Flex the hoses to make sure that they have not become brittle. The electrical system that I am referring to is the engine compartment wiring. Here we are looking for unsupported or frayed wires. Special attention should be paid to the high current wiring such as the alternator and battery wires. For the exhaust system, we are looking for leaks and parts that appear to be worn or loose.

The brake inspection is more complicated. If in doubt, have a professional do the inspection. A good inspection involves getting under the bus, and that must not be done without properly supporting the bus. This inspection primarily involves checking for bad axle seals, sufficient lining thickness, and proper brake adjustment. All of the manuals focus on brake adjustment from a brake performance standpoint which is correct. However, from a fire standpoint we are looking for brakes that are so far out of adjustment that the “S” cams (which move the shoes into the drums) hang up and cause brake drag. Brake drag, where the brakes fail to fully release, is a major cause of brake fires. One very large caution: do not rely on automatic brake adjusters. My bus had an automatic adjuster seize up and allowed the brake adjustment to become so bad that the brakes for that wheel would not release properly. I detected the problem during a detailed inspection and avoided what surely could have been a brake fire.

One last obvious “soap box” observation about pre-trip and DOT type inspections: our buses generally have considerable mileage on the components, and it just makes good sense to go the extra mile to make sure our vehicles are safe.

Beyond proper inspection and good maintenance procedures, there is not much that we can do to prevent fires with one possible exception. In the engine compartment, the exhaust manifolds can reach very high temperatures when the engine is working hard. In fact they can become cherry red under extreme conditions. This is an excellent ignition source for any combustible material that might be nearby. One can consider wrapping the exhaust manifolds with one of the new ultra-high temperature resistant materials. This will not only decrease the ignition source, it will make our bedrooms cooler. Indeed, if you have a turbocharged engine, it will give you a slight HP increase since it delivers more heat energy to the turbo. We have kits available at: http://rvsafetysystems.com.

Even if we do all of the proper inspection/maintenance/prevention procedures, there is always a slight chance that we could experience a fire. The only way to minimize the damage is early detection. All new buses are required to have fire detection systems. One would think that those systems would be available to the aftermarket. I have done considerable research and can not find a self-standing system. I suspect that the OEM systems are built into the complex on-board computer systems that exist today and don’t lend themselves to the aftermarket. While I continue to search for a system, I have taken the approach that I will design a system that can be readily adapted to the aftermarket. Prototypes should be available for preliminary testing early in the first quarter of 2004.

Update, January 2005. The Fire detection system noted above has been in the beta test phase for several months and will be in the manufacturing phase by spring of 2005. For more information go to: http://rvsafetysystems.com

EG-400 Engine and Generator Fire Detection System

Fire suppression systems

No matter how much effort we put into prevention and detection, we must still be able to suppress a fire if it does occur. Perhaps it is not our vehicle that catches fire, and we want to be prepared to help someone else. What are our options? In this section we will discuss both handheld and mounted fire suppression systems. The options are almost limitless.

First let’s discuss the different classes of fires so that we can compare the various suppression material capabilities against the classes of fires:

- Class A: Ordinary combustibles such as wood, paper, cloth, rubber and some plastics

- Class B: Flammable combustible liquids such as gasoline, kerosene, paint, propane

- Class C: Energized electrical equipment (becomes a Class A fire when the power is shut off)

- Class D: Combustible metals such as magnesium

Secondly, it is important to understand that fire is a chemical reaction which requires a combustible material, oxygen (air) and heat. Heat can also potentially be the ignition source of a fire. Heat can increase the temperature of liquid fuels to the point that sufficient vapors are given off for ignition to occur. Heat sources, such as exhaust systems, can also be of sufficient temperature to cause ignition. Take away one of the three components (fuel, oxygen, or heat) and the fire is extinguished.

Next let’s discuss the various materials and extinguishers used in fire suppression systems. The list of materials includes:

- Dry chemical

- Carbon Dioxide

- Halon and Halon replacement

- Water (perhaps from our RV supply system)

- Water based foam/surfactant

Each of these materials has good and bad characteristics. Let’s look at each.

Dry Chemical extinguishers use various powders such as monoammonium phosphate, potassium bicarbonate, and sodium bicarbonate. The extinguishers are pressure vessels and are pressurized with nitrogen. They are the typical extinguishers that we buy and have in our house and vehicles. Most are rated for Class B and C types of fire, while some have a reduced rating for Class A fires. They put out the fire by covering the combustible material with a coating of powder which separates the fuel from the oxygen supply. They do a good job of putting out the initial fire. However, they have limited value to stop re-ignition or flashover fires caused by high-temperature sources. The powder is a mess to clean up, and can cause some damage to machinery. While the powders do not pose a chemical health risk, breathing small size airborne particles can be a significant concern. There have been reported cases where the dry powder compressed into a “brick-like” mass in the vessel which compromised the capability of the extinguisher.

Carbon Dioxide extinguishers are filled with CO2 gas under extreme pressure. They are rated for Class B and C fires only. They put out the fire by displacing the oxygen. CO2 also cools down the material since it is very cold when it leaves the extinguisher (remember the old Navy stories about using these extinguishers to cool down the beer?). Carbon Dioxide is not common in home or vehicle applications.

Halon and Halon replacement fire extinguishers are extremely effective for Class B & C fires (some suppliers also rate their units for reduced ratings for Class A fires). Manufacture of Halon has been outlawed for 10 years, because it is an ozone depleting gas. However, there are abundant quantities of recycled Halon that reportedly will service the market for 10 years. As is the case with Freon, there are now replacement gases which can be used, albeit with some reduction in effectiveness. One of those is DuPont’s FE-36. Because Halon/Halon replacement is discharged as a gas, it does not have any clean-up issues. It extinguishes the fire by displacing the oxygen and has significant cooling capability. It is rated “good” for preventing re-ignition or flashover. It so good at oxygen depletion, that it is imperative that the area be evacuated immediately to prevent oxygen-depravation related health problems (up to and including death). Other than the oxygen depletion issue, Halon has no health hazards.

Pure water systems are not good extinguishers. Water should never be used on Class B, C, or D fires. Water extinguishes fire by removing the heat from the chemical reaction. Several folks on the various Bus and RV internet boards have talked about adapting high volume/pressure water pumps to their on-board water supply and having hoses available for fire fighting. While that option is better than nothing, it will not address liquid (Class B) fires that are a large part of engine compartment fires. Water will also be marginal, at best, fighting a tire fire if brake fires progress to the tires, since tire fires are essentially a Class B fire because of the large amount of hydrocarbons in the rubber material. Investment in an adequate water pump would go a long ways toward purchasing a highly-effective fire extinguisher.

The last category of materials is water-based foam and water-based surfactants. These are really two different materials, even though they have some characteristics in common. Foam is referred to as AFFF (aqueous film forming foam). The chemicals which are used to manufacture this product are often highly fluorinated and are currently being scrutinized by the EPA. AFFF extinguishers are highly effective for Class B fires. AFFF is considered toxic and corrosive.

The real shining stars are the water-based surfactants. This category is the latest technology and is being widely accepted and approved by fire fighting agencies, as well as racing governing bodies. They are biodegradable, non-toxic, and environmentally friendly. They are highly effective on Class A and B fires and are said to have a three-pronged attack:

· Reduces vapor release

· Absorbs incredible amounts of heat

· Effectively disperses and emulsifies liquid fuel

There are several trade names for the materials: Cold Fire, FireX and FireAde to name a few. As noted above, there are no health issues, clean-up is easy, and it is environmentally friendly. The only possible drawback is that since, it is water based, it can freeze at low temperatures.

For the past 10 years, I have followed the development and implementation of Cold Fire in the racing industry (NHRA). I used to work with the safety crews as I did my work for my company. I talked to the Cold Fire representative at his first race and when he told me about his product, I thought he was barking up a very big tree. Fires in Top Fuel cars are horrendous. As the testing phase continued, I became a real believer. Today, Cold Fire 302 and Fire X Plus are approved products for all classes according to the 2004 NHRA rule book. I have seen the products work first hand and without question, they are unparalleled in their fire suppression capability (equal to, or perhaps greater, than Halon systems in many situations involving a lot of liquid fuel and high temperature metal parts). In addition, because of the tremendous cooling capability, the drivers are much better protected from the intense heat.

One other major issue to consider is maintenance. I would suspect that each reader has at least one dry chemical fire extinguisher whose pressure is below the acceptable range on the gauge. That extinguisher must be replaced or recharged. Recharging is not inexpensive and is a pain since we have to find a supplier, drop off the extinguisher, and then go back and pick it up. The new surfactant systems can be owner charged and maintained. Indeed, the extinguishers are often shipped uncharged and are charged by the owner. The process is simple. The concentrated material is mixed with water in the extinguisher. It is then charged with compressed air. Since those of us with air brakes systems have 125 PSI air, we can easily charge and maintain the extinguishers.

Bottom line, it is my strong opinion that the materials of choice should be water-based surfactants or Halon/Halon replacement. The both have amazing fire suppression capability and are the only systems sanctioned by the majority of racing governing bodies for on-board fire extinguishers. These are the only products that are sold by my company. Of the two, my vote is the surfactant materials because of the ease of maintenance, with the only drawback being the freezing issue during storage.

Extinguishers can either be mounted permanently to the coach, or they can be

Of the handheld variety.

Now, let’s talk about handheld and mounted types of fire extinguishers, since they both have applications in Bus/Motorhomes.

The need for handheld fire extinguishers is obvious. While DOT requirements do not apply to RVs, we should still carry fire fighting equipment. Handheld Halon or surfactant type extinguishers are fairly comparable in weight, although the Halon systems can be up to twice the cost. A good quality surfactant type extinguisher with adequate capacity weighs about 15 pounds and costs around $140. Larger units with greater capacity weigh about 30 pounds and cost around $160. My recommendation is to have two of the smaller size units for the coach. One should be located inside the coach and another in an easy-to-get-to bay.

The need for a permanently mounted extinguisher system is less obvious. Given the large percentage of engine compartment fires in the Finland studies, there is a good argument for a permanently mounted extinguishing system in the engine compartment ready to fight a big Class B fire. That is the approach that racing regulations favor and these systems use racing technology. Again, the systems will use surfactant or Halon material. The actual vessel can be located remotely, with a hose or tubing running to the engine compartment. The system can be triggered manually with a push/pull cable, or automatically with a heat sensitive head. The same system could be used in the generator compartment. These surfactant systems are in the $300-$350 range depending on the specific configuration. The system we stock is a surfactant system based stainless steel tank designed for easy mounting. It can be charged in place. Because of the shape of the vessel, it can withstand freezing during storage. We are also distributor for mounted Halon systems, but we do not stock them, because we believe that the surfactant systems are better suited to the Bus/motorhome application.

A special warning

It is extremely important for the reader to exercise extreme caution when attempting to fight any fire. This is especially true when an interior fire is encountered. If it is a very small fire, such as a stove fire, it might be possible to quickly extinguish it safely. However, it is imperative that everyone onboard is quickly evacuated and that you have quick access to the exit. Any fire gives off toxic vapors as well as heavy smoke. The interior of an RV has a very small volume and even a small fire will quickly produce deadly levels of smoke and toxic vapors. It is imperative that personal safety is the overriding consideration. If in doubt, get out of the vehicle.

If the fire is in the engine or generator compartment or is a brake/tire fire, it might be possible to attempt to fight the fire with a high performance extinguisher where a safe distance can be maintained. Again, personal safety is paramount.

* * *